Introduction

Accurate board foot calculation underpins cost estimation, inventory management and waste control in woodworking, construction and forestry. Yet common missteps—ranging from unit mismatches to improper rounding—can distort material requirements by significant margins. This analysis identifies frequent board foot calculation mistakes, examines their origins, quantifies their impact and offers strategies to ensure reliable outcomes. An understanding of how to calculate board feet and mastery of the board foot formula form the foundation for error mitigation.

Defining the Board Foot and the Board Foot Formula

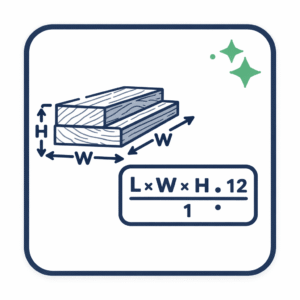

By industry standard, one board foot (BF) equals 144 cubic inches of lumber. The board foot formula translates mixed-unit dimensions into this volume unit:

Board Feet = (Thickness in inches × Width in inches × Length in feet) ÷ 12 [Wikipedia]

Key elements:

- Thickness and width in inches.

- Length in feet.

- Division by 12 converts square-inch-feet to cubic inches (12 in²·ft = 144 in³).

Common Unit Mismatches

Inches vs. Feet Confusion

A pervasive error arises when length is recorded in inches instead of feet. Entering 96 inches rather than 8 feet into the formula multiplies calculated volume by 12. Implement input validation in digital tools to flag implausible values (e.g., length > 48 ft).

Nominal vs. Actual Dimensions

Use of nominal dimensions for finished lumber yields inflated board footage:

Nominal BF (2×4×10) = (2 × 4 × 10) ÷ 12 = 6.67 BF Actual BF (1.5×3.5×10) = (1.5 × 3.5 × 10) ÷ 12 = 4.38 BF

Nominal calculation overstates true volume by 52 percent. For dimensional lumber, adjust nominal values to actual measurements before applying the board foot formula. [Wikipedia]

Rounding and Significant Figures

Premature Rounding

Rounding intermediate results inflates cumulative error. In a project with 50 boards, rounding each board’s footage to the nearest tenth invites discrepancies exceeding a full board foot.

- Exact BF per board: 6.67

- Rounded BF per board: 6.7

- Total (exact): 6.67 × 50 = 333.5 BF

- Total (rounded): 6.7 × 50 = 335.0 BF (+1.5 BF error)

Retain at least four significant figures during individual calculations and round only final totals.

Significant Figure Misapplication

Overprecision—reporting results to excessive decimal places—can imply unwarranted accuracy. Board foot estimates in field contexts generally accept one decimal place; beyond that, measurement variability outweighs the precision.

Ignoring Defect and Waste Factors

Defect Inventory Overlook

Knots, wane, warp and splits reduce usable footage. Incorporate species-specific defect percentages (typically 5–10 percent) into orders. Conduct visual inspection and record defect rates to refine future estimates.

Omitted Waste Margins

Sawing, trimming and machining generate offcuts. Failing to include a machining waste factor (commonly 3–5 percent) leads to material shortages mid-project.

- Apply a minimum 5 percent machining waste multiplier to total BF requirements.

- Track actual waste rates on projects to calibrate future factors.

Log Scaling Errors

For uncut logs, empirical rules estimate potential board footage:

BF (Doyle Rule) = ((D − 4) ÷ 4)² × Length, where D is diameter at small end in inches, Length in feet. The Doyle rule underestimates large diameters and overestimates smaller logs. [Penn State Extension]

Use multiple scaling rules (Doyle, International ¼-in) and average results. Mill and weigh test logs to generate localized correction factors when feasible.

Digital Tool Pitfalls

Improper Units Configuration

Web-based and mobile calculators often default to inches or centimeters. Selecting the wrong unit system results in egregious miscalculations without explicit warning.

Data Entry Errors

Typographical mistakes in digital forms remain common. Implement input masks (e.g., requiring decimal points) and range checks. Offer live previews of results to catch anomalies.

Quality Assurance and Cross-Validation

Auditing digital calculator outputs against manual computations fosters confidence. Compute BF manually for a random 10 percent sample and compare with batch-calculator results. Investigate discrepancies > 2 percent. Implement periodic review of material usage versus estimated BF to detect systematic miscalculations.

Training and Standardization

Document step-by-step guidelines for measurement and calculation, including:

- Measurement technique (caliper placement, tolerances).

- Input conventions (units, nominal vs. actual).

- Rounding and waste factors.

Hands-on workshops reinforce correct practice. Practical measurement exercises reduce board foot errors significantly. [Woodworking Institute]

Final Considerations

Mitigating board foot calculation mistakes demands a multifaceted approach: mastering how to calculate board feet through the board foot formula, rigorously distinguishing units and dimensions, applying disciplined rounding and waste allowances, and employing robust quality-assurance protocols. Cross-validating manual and automated outputs, training personnel and refining defect and scaling factors ensures reliable volume estimates that optimize material usage, control costs and minimize project disruptions. Continuous process improvement sustains accuracy gains, keeping board footage calculations a precise cornerstone of wood-based operations.