Introduction

The board feet calculator stands as a cornerstone in the workflow of carpenters, contractors and timber merchants. By automating the conversion of length, width and thickness measurements into standardized volumetric units, these tools mitigate manual errors, accelerate material estimation and streamline cost projections. Understanding how to calculate board feet manually lays the foundation for effective use of digital calculators, while appreciation of the board foot formula informs quality control when leveraging automated platforms. This article traces the evolution of board feet calculators, dissects their underlying mathematics, surveys available solutions, assesses practical deployment considerations and anticipates future enhancements.

Origins of Board Foot Computation

The concept of a board foot predates digital computation, originating in 19th-century North America to address the need for a uniform lumber measurement. In 1840, the American Lumber Association codified the definition: “One board foot equals the volume of a one-inch thick board, one foot wide and one foot long.” [Wikipedia] Early sawmills calculated board footage by stacking boards into measured piles and manually counting layers. As production volumes grew, this manual approach became labor-intensive and prone to discrepancies, prompting the first mechanical slide-rule calculators and tabulated charts in the early 20th century.

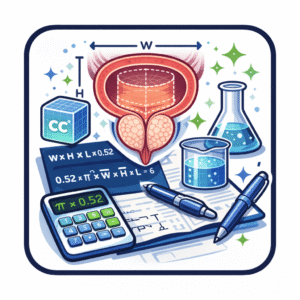

Mathematical Foundation: Board Foot Formula

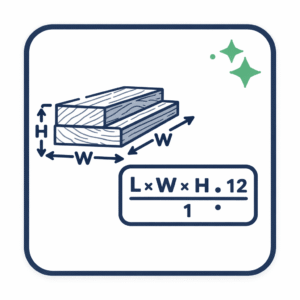

Central to all calculators is the board foot formula, which converts mixed-unit dimensions into a volume measure expressed in board feet (BF). By definition:

Board Feet = (Thickness in inches × Width in inches × Length in feet) ÷ 12 [Wikipedia]

The derivation hinges on three relationships:

- Cross-sectional area (in²) = thickness (in) × width (in)

- Length (ft) measured in feet

- Conversion factor: one board foot equals 144 cubic inches (12 in² × 1 ft)

For a board measuring 2 in × 6 in × 8 ft:

Board Feet = (2 × 6 × 8) ÷ 12 = 8 BF

Manual Calculation Methods

Tape-Measure and Calculator

Despite the prevalence of digital tools, many professionals retain proficiency in manual computation:

- Measure thickness and width in inches, length in feet.

- Multiply thickness × width × length.

- Divide by 12.

- Sum results across multiple boards, deferring rounding until final total to limit cumulative error.

Adhering to precise fractional entries (e.g., 1 3/8 in recorded as 1.375 in) prevents rounding-induced discrepancies, particularly over large inventories.

Log Scaling Rules

For uncut logs, empirical formulas estimate potential board footage:

Board Footage (Doyle Rule) = ((Diameter – 4) ÷ 4)² × Length, where diameter measured at small end in inches, length in feet. Loggers accept that the Doyle rule underestimates yield for large diameters and overestimates smaller logs, producing systematic error up to 25 percent in some species. [Penn State Extension]

Digital and Web-Based Calculators

OmniCalculator’s Board Foot Tool

OmniCalculator offers a free, browser-based board feet calculator that prompts entry of length (ft), width (in) and thickness (in), returning results instantly. As the site notes, “This board foot calculator allows you to quickly estimate the volume of hardwood lumber you want to buy.” [OmniCalculator]

Specialized LumberYard Software

Commercial platforms such as EconomyLumberCo’s construction calculators integrate board foot computation alongside decking and concrete modules. These solutions often support batch processing, enabling users to upload CSV files with dimension datasets and receive aggregate board footage with a single click.

Mobile Applications

Smartphone apps—ProTrack, WoodCalc and similar—leverage built-in sensors to assist in direct measurement. Users align virtual calipers on the screen to gauge width and thickness, input length manually and let the app execute the board foot formula. A pilot by Hardwood Industries reported ±5 percent accuracy relative to manual measurements, citing device calibration as the primary source of variance.

3D Scanning Systems

Leading sawmills and high-volume yards employ laser or structured-light scanners to capture board geometry and feed 3D meshes into proprietary volumetric calculators. Reported mean absolute error rates for such systems fall below 3 percent, drastically reducing labor costs and waste from miscalculation.

Validation and Accuracy Considerations

| Method | Mean Error | Throughput | Use Case |

|---|---|---|---|

| Manual calculation | < 1 percent | Low (tape + calc) | Small projects |

| OmniCalculator (web) | < 0.5 percent | Instant | On-demand checks |

| Mobile apps | ± 5 percent | Instant | Jobsite convenience |

| Batch CSV import (LumberYard SW) | < 1 percent | High | Inventory management |

| 3D scanning | < 3 percent | Very high | Industrial sawmills |

Integration Into Workflow

Procurement and Cost Estimation

A precise board footage figure underpins cost projections. Multiplying total BF by the prevailing lumber cost per board foot yields material expense. As of late 2025, U.S. softwood lumber futures closed near 562 USD per 1,000 BF, or 0.562 USD per BF. [Trading Economics] Contractors incorporate these indices into bids, adjusting for species, grade and regional supply dynamics.

Inventory Management

Batch-processing calculators link directly to warehouse databases, tracking on-hand board footage in real time. Alerts for low-stock thresholds maintain production continuity and prevent project delays.

Quality Control

Variance analysis—comparing expected BF from calculator outputs against actual sawn footage—identifies process drift. A consistent negative bias may indicate calibration issues in measurement tools or scanner misalignment.

Common Calculator-Related Pitfalls

- Unit Confusion: Entering length in inches rather than feet leads to twelvefold errors.

- Nominal vs. Actual Dimensions: Confusing nominal lumber sizes (e.g., 2 × 4 nominal) with actual planed dimensions inflates estimates by up to 30 percent.

- Early Rounding: Rounding intermediate values compounds error across multiple boards.

- Ignoring Defects: Calculator outputs assume perfect boards; real-world factors—knots, wane, warp—reduce usable footage. Including a waste percentage (commonly 10 percent) guards against shortfalls.

Future Directions

Advances in machine vision and edge computing promise fully automated, on-the-fly volumetric analysis via augmented-reality headsets or integrated saw station cameras. Deep-learning models trained on diverse lumber species aim to distinguish defects and grade quality in real time, refining board foot estimates beyond mere geometry. Integration with blockchain-based supply-chain platforms could also ensure traceability of volumetric data across mill, yard and jobsite.

Final Considerations

Board feet calculators—whether web-based widgets, mobile apps or industrial scanners—embody the intersection of traditional measurement science and modern automation. Mastery of how to calculate board feet manually empowers users to validate and interpret digital outputs, while understanding the board foot formula assures consistency across platforms. By selecting tools aligned with project scale, integrating them into procurement and inventory systems and maintaining robust quality-control protocols, industry professionals optimize material usage, reduce waste and enhance financial forecasting. As technologies evolve, calculators will become ever more integrated, intelligent and indispensable in wood product supply chains.