How to Calculate Board Feet

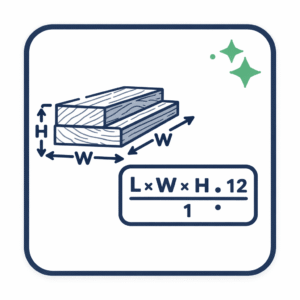

Calculate board feet (a lumber volume measure). Classic formula:

Board feet = Length (ft) × Width (in) × Thickness (in) ÷ 12

Results

| Board feet (per piece) | — bf |

|---|---|

| Total board feet | — bf |

| Total volume | — ft³ |

| Total volume | — m³ |

Tip: If you have metric dimensions, the calculator converts to the standard board-foot definition (1 bf = 144 in³).

Introduction

Board feet serve as the primary unit for quantifying lumber volume in North America. A single board foot equates to one foot in length, one foot in width and one inch in thickness, or 144 cubic inches of wood. [Wikipedia] Mastery of the board foot formula explained herein enables accurate material estimation, cost projection and waste reduction across woodworking, construction and forestry industries. This article dissects the underlying principles, illustrates methods for manual and digital calculation, highlights common board foot calculation mistakes, addresses board feet errors, surveys available board feet calculator tools and examines implications for board feet pricing and lumber cost per board foot.

Origins and Definition

The concept of the board foot emerged during the 19th century as lumber production scaled to meet expanding urban demand. Early sawmill operators required a standardized metric to evenly price irregularly shaped boards and logs. In 1840, the American Lumber Association endorsed the current definition, establishing the now-familiar rule:

“One board foot equals the volume of a one-inch thick board, one foot wide and one foot long.” [Wikipedia]

This simple volume unit persists despite the transition from rough-hewn beams to dimensioned lumber. Distinct terms apply for board feet rough lumber, measured on actual sawn dimensions, and dimensional lumber board feet, calculated on nominal dimensions (e.g., a “two by four” measured as 2 × 4 in despite actual size of 1 ½ × 3 ½ in). Understanding the divergence between nominal and actual sizes proves essential when calculating material needs or verifying invoices.

Manual Calculation Methods

Proportional Formula

The most ubiquitous approach relies on the proportional relationship between board dimensions and volume:

Board Feet = (Thickness in inches × Width in inches × Length in feet) ÷ 12 [Wood Magazine]

- Thickness and width are measured in inches.

- Length is measured in feet.

- Division by 12 converts cubic inches into board feet (144 in³ per BF).

For a board measuring 2 in × 6 in × 8 ft:

Board Feet = (2 × 6 × 8) ÷ 12 = 8 BF

Cubic‐Inch Conversion

An alternative expresses volume entirely in cubic inches:

Board Feet = Total Cubic Inches ÷ 144

This method consolidates irregular shapes—for instance, tapering timbers—by summing individual section volumes before conversion.

Log Scaling (Doyle Rule)

For raw logs, the Doyle formula approximates usable board feet:

Board Footage (Doyle) = ((D − 4) ÷ 4)² × L, where D is diameter in inches, L is length in feet.

Loggers use this to forecast yield prior to sawing, acknowledging that it underestimates large diameters and overestimates smaller ones.

Digital Tools and Software

Web‐Based Calculators

Online utilities democratize volume computation. Omnicalculator’s lumber volume calculator prompts entry of dimensions and outputs board footage instantaneously. Users report: “This board foot calculator allows you to quickly estimate the volume of hardwood lumber you want to buy.” [OmniCalculator]

Integrated Imaging Software

Laser scanners and 3D optical devices integrate with board feet calculator modules to facilitate non-contact measurement. Such systems capture cross-sectional profiles and compute total volume through automated planimetry, largely eliminating board foot calculation mistakes inherent to manual methods.

Mobile Applications

Smartphone apps incorporate virtual rulers and angle sensors to approximate width and thickness, applying the board feet equation internally. While offering convenience, their accuracy (± 5 percent) depends on sensor calibration and user technique.

Avoiding Common Errors

Practitioners must recognize sources of board feet errors:

- Unit Mismatch: Confusing inches and feet leads to over- or underestimation by factors of 12.

- Nominal vs. Actual Dimensions: Using nominal sizes for planed lumber without adjustment results in inflated board footage.

- Rounding Practices: Rounding early in calculations compounds discrepancies; defer rounding until final results.

- Neglecting Defects: Checking for knots, wane or warp reduces effective board footage; incorporate a waste percentage when ordering.

Applications in Purchasing and Pricing

Calculating Material Requirements

Estimating the correct dimensional lumber board feet prevents both shortages and excess stock. For projects requiring flooring, framing or cabinetry, specification sheets often list total BF needed. Use:

Total BF = Σ (Piece Count × (T × W × L ÷ 12))

Accounting for a standard 10 percent waste factor further refines ordering volumes.

Pricing Models

Wholesale and retail transactions typically quote lumber cost per board foot. As of December 31, 2025, the lumber futures price on the CME stood at 539 USD per 1,000 BF. [Trading Economics] Regional sawmills may list spot prices ranging from 0.45 to 0.80 USD per BF depending on species, grade and moisture content. Accurate board foot estimates directly influence total cost:

Total Cost = Total BF × Lumber Cost per Board Foot

Advanced Techniques and Calculators

Batch‐Processing Tools

Software suites designed for lumber yards perform bulk calculations on entire inventories. They ingest dimension datasets, apply the board feet formula and generate material manifests with aggregated BF totals. Integration with inventory management ensures real-time tracking of available stock.

Three‐Dimensional Scanning

Emerging lumber volume calculator technologies use LiDAR and structured light to reconstruct board geometry. Proprietary algorithms compare scanned meshes against idealized rectangular solids, calculating cubic volume and converting to board feet. These systems report mean absolute errors under 3 percent, offering high throughput in industrial settings.

Regulatory Standards and Industry Guidelines

The National Hardwood Lumber Association allows up to a 4 percent variation in board footage tally on stamped lumber; some suppliers guarantee 100 percent delivery accuracy under penalty terms for shortages beyond 1 percent. [NHLA Standards]

Final Considerations

Accurate board foot determination underpins efficient material procurement, cost control and waste minimization. Mastery of the board foot formula explained above, whether executed via pen and paper or advanced board feet calculator tools, guards against board foot calculation mistakes and board feet errors. Adopting standardized protocols for measurement, leveraging digital technologies and aligning pricing with reliable indices ensures robust planning across woodworking, construction and forestry applications. As scanning and automation advance, the precision of board footage estimation will continue to improve, reinforcing lumber volume calculation as a data-driven practice.