Introduction

Rough-sawn and surfaced (dimensional) lumber represent two distinct stages in wood processing, each with unique implications for volume estimation, cost analysis and project planning. Central to these considerations is the question of how to calculate board feet accurately in both contexts, employing the established board foot formula while accounting for nominal versus actual dimensions. This article examines historical practices, measurement methodologies, comparative analyses, pricing impacts, tool selection and industry standards, weaving precise data and expert commentary to guide practitioners in forestry, construction and woodworking.

Definitions and Context

Rough Lumber

Rough lumber refers to boards that have been sawn from logs but not planed, surfaced or trimmed to final thickness and width. Its dimensions correspond closely to the kerf of the saw and initial shrinkage allowances:

- Nominal Dimensions – the size assigned at rough cut, commonly used for ordering (e.g., a nominal 2×4 measures approximately 2.0 in × 4.0 in before surfacing). [Wikipedia]

- Actual Dimensions – for rough lumber, actual equals nominal until planing occurs; moisture content and sawing tolerances may introduce minor variance.

Dimensional Lumber

Dimensional lumber has been dried and planed to standardized finished sizes:

- Nominal Dimensions – retained for identification (e.g., “2×4”).

- Finished (Actual) Dimensions – result from planing and drying (e.g., 1½ in × 3½ in for a 2×4). [Wikipedia]

Historical Evolution of Board Foot Measurement

The board foot unit emerged in the 19th century to standardize lumber commerce in North America. The American Lumber Association’s 1840 definition stated: “One board foot equals the volume of a one-inch thick board, one foot wide and one foot long.” [Wikipedia] Early merchandising relied on rough-sawn volume, stacking boards into measured piles. As planers and surfacing machines proliferated, the industry adopted nominal sizing conventions for finished boards, simplifying communication but decoupling nominal and actual volumes.

Mathematical Foundations: Board Foot Formula

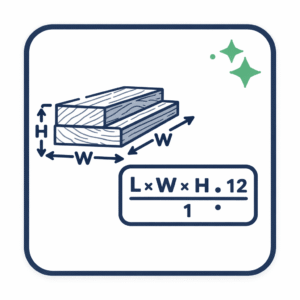

By definition, one board foot (BF) equals 144 cubic inches of wood. The board foot formula calculates BF from mixed-unit dimensions:

Board Feet = (Thickness in inches × Width in inches × Length in feet) ÷ 12 [Wikipedia]

The derivation hinges on three relationships:

- Cross-sectional area (in²) = thickness (in) × width (in)

- Length (ft) measured in feet

- Conversion factor: one board foot equals 144 in³ (12 in² × 1 ft)

Calculation Procedures

Rough Lumber Board Foot Calculation

- Measure actual thickness (T) and width (W) with calipers or rule.

- Record board length (L) in feet.

- Apply board foot formula:

BF = (T × W × L) ÷ 12

- Sum results for multiple pieces, deferring rounding until the final total.

Because rough lumber dimensions reflect true sawn size, these values yield accurate cubic volumes prior to surfacing.

Dimensional Lumber Board Foot Calculation

- Use nominal thickness (Tₙ) and width (Wₙ) for calculation (e.g., 2 in × 4 in).

- Measure actual length (Lₐ) in feet.

- Compute BF using the same formula:

BF = (Tₙ × Wₙ × Lₐ) ÷ 12

- Adjust orders by recognizing that actual cross-sectional area is smaller, typically by 14–25 percent depending on nominal size.

Quantitative Comparison

| Specification | Rough (in) | Dimensional Nominal (in) | Finished Actual (in) | Board Feet (Rough) |

Board Feet (Nominal) |

|---|---|---|---|---|---|

| Cross-section (T×W) | 2.0 × 4.0 | 2.0 × 4.0 | 1.5 × 3.5 | (2.0×4.0×100)/12 = 66.7 | (2.0×4.0×100)/12 = 66.7 |

| Length (L) | 100 ft | ||||

The nominal calculation (66.7 BF) overstates true volume relative to finished lumber by approximately 14.4 percent (actual finished: 43.75 BF). Recognizing these distinctions guides accurate material estimation and cost control.

Pricing Implications

Board footage underpins lumber pricing. Futures contracts on the Chicago Mercantile Exchange trade in dollars per 1,000 BF; as of December 31, 2025, lumber futures closed at 538.50 USD per 1,000 BF. [Trading Economics] Retail sawmill prices vary by species, grade, moisture content and dimensional status:

- Rough Lumber commands premiums or discounts based on yield and surfacing costs.

- Dimensional Lumber uses nominal BF pricing, simplifying invoicing despite lower actual volume.

A buyer requesting 1,000 nominal BF of 2×4 should anticipate receiving approximately 840 actual board feet of finished material, affecting per-unit costs when comparing rough and surfaced offerings.

Tools for Measurement and Calculation

- Manual and Spreadsheet Methods – Worksheets and templates apply the board foot formula to input dimensions and sum results, with manual cross-checks ensuring integrity.

- Web-Based Calculators – Online utilities such as OmniCalculator’s board foot tool prompt dimension entry and return results instantly. “This board foot calculator allows you to quickly estimate the volume of hardwood lumber you want to buy.” [OmniCalculator]

- Mobile Applications – Apps like ProTrack and WoodCalc leverage virtual calipers and unit toggles, executing the board foot formula internally.

- Integrated Yard and Mill Software – Commercial platforms ingest length and cross-section data via scanners or CSV uploads, batch-processing thousands of entries with negligible manual intervention.

Industry Standards and Guidelines

The National Hardwood Lumber Association (NHLA) and the American Softwood Lumber Standard (PS 20) define tolerances for nominal versus actual dimensions in softwood lumber. [NHLA Standards] Hardwood lumber is typically sold by actual dimension and board foot, eliminating nominal conventions.

Best Practices and Common Pitfalls

- Clarity on Dimension Basis – Specify whether calculations use rough sawn or nominal dimensions to prevent ordering errors.

- Precision in Measurement – Record fractional inches to three decimals (e.g., 1.375 in) and defer rounding until summation.

- Accounting for Waste – Incorporate species-specific shrinkage factors (up to 5 percent) and machining allowances when estimating rough-to-finished yield.

- Cross-Validation – Compare manual and digital outputs, or rough and dimensional estimates, to detect inconsistencies early.

Final Considerations

Accurate estimation of board feet for rough versus dimensional lumber hinges on mastery of how to calculate board feet through the board foot formula, cognizant of nominal-actual distinctions and industry standards. Whether employing tape measures and calculators, web-based tools or integrated mill software, practitioners must align their methodology with project specifications, pricing conventions and waste allowances. A disciplined approach to measurement, calculation and validation ensures reliable material procurement, transparent cost analysis and minimized wood waste across forestry, construction and woodworking operations.