Introduction

The unit known as the board foot underlies material estimation, procurement and waste management within woodworking, construction and forestry sectors. At its core, the question of how to calculate board feet hinges on a straightforward proportional relationship among length, width and thickness. Yet practical implementation reveals nuances—from dimensional lumber conventions to digital automation—that shape accuracy and efficiency. This article examines the definition, mathematical underpinnings and operational context of the board foot formula, integrating historical perspective, expert commentary, quantitative data and actionable guidelines.

Historical Background

The board foot emerged in mid-19th century North America as sawmills transitioned from hand-hewn timbers to mechanized production. According to the American Lumber Association’s 1840 standard, “One board foot equals the volume of a one-inch thick board, one foot wide and one foot long.” [Wikipedia] Early operators documented volume by stacking boards into uniform piles, relying on basic counting rather than precise measurement. During the early 20th century, veneer mills and planing operations introduced nominal sizing conventions, giving rise to distinctions between board feet rough lumber and dimensional lumber board feet.

Principles of Board Foot Calculation

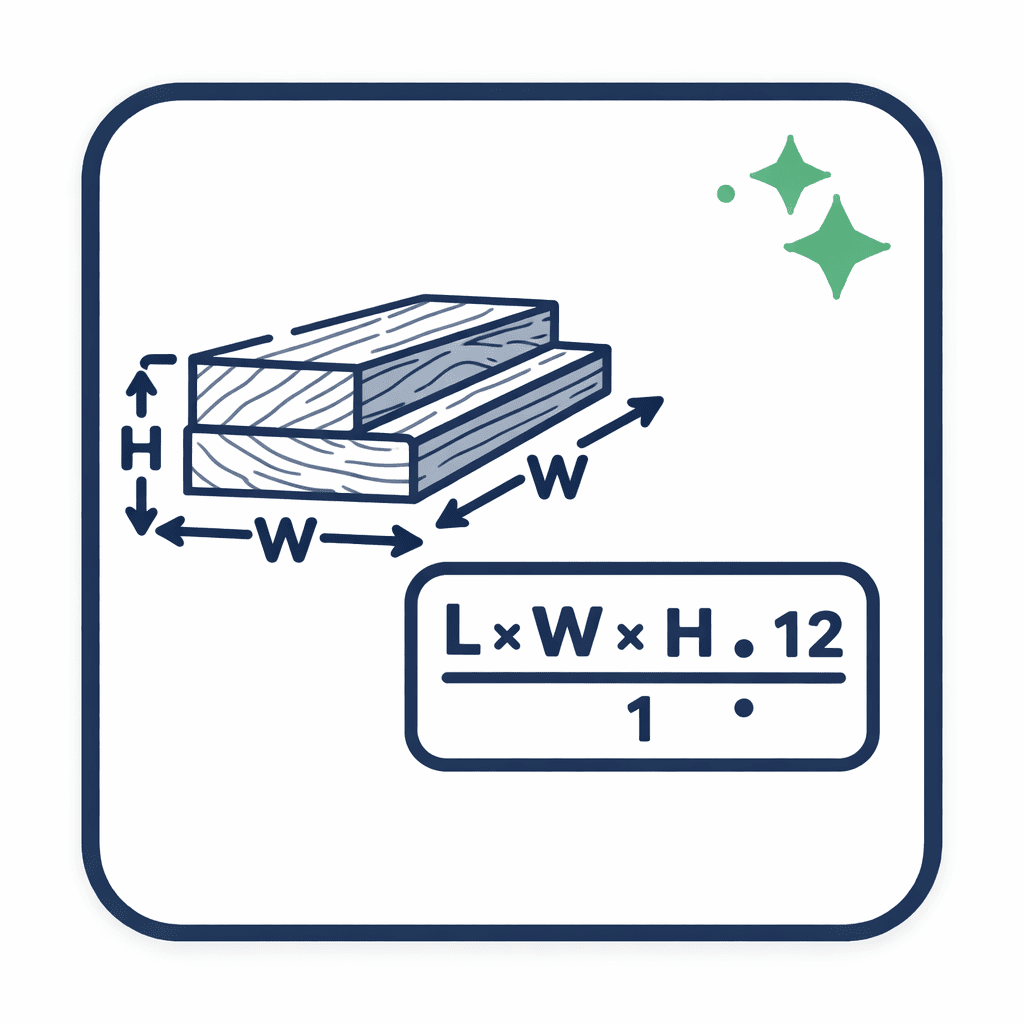

The foundational board foot formula expresses volume in cubic inches converted to board feet (BF). By definition, one BF equals 144 cubic inches. The relationship can be stated as:

Board Feet = (Thickness (in) × Width (in) × Length (ft)) ÷ 12

Division by 12 reconciles inches-based cross-sectional area (in²) with length in feet. A board measuring 1 in × 12 in × 1 ft thus yields:

Board Feet = (1 × 12 × 1) ÷ 12 = 1 BF

Mathematically, the formula arises from:

- Cross-sectional area in square inches: Thickness × Width

- Linear dimension in feet: Length

- Conversion factor: 1 BF = 144 in³ = 12 in² × 1 ft

Manual Calculation Methods

Direct Measurement

In field settings, carpenters and lumber inspectors perform manual calculation using tape measures and calculators:

- Measure thickness (T) in inches.

- Measure width (W) in inches.

- Measure length (L) in feet.

- Compute BF: (T × W × L) ÷ 12.

For example, a 2 in × 4 in × 10 ft board produces:

(2 × 4 × 10) ÷ 12 = 6.67 BF

Total Cubic-Inch Conversion

Projects involving irregular or tapered stock benefit from first calculating total cubic inches, then dividing by 144:

Board Feet = Total Cubic Inches ÷ 144

If a beam comprises sections of differing cross-section, summing each section’s volume ensures accuracy prior to conversion.

Log Scaling Rules

For rough logs, the Doyle scale offers an empirical estimate:

BF (Doyle) = ((D − 4) ÷ 4)² × L, where D = diameter at small end (in), L = length (ft). Loggers use this to forecast yield prior to sawing, acknowledging systematic error up to 25 percent in some species. [Penn State Extension]

Advanced Formulaic Considerations

Nominal vs. Actual Dimensions

Dimensional lumber board feet often derive from nominal sizes (e.g., 2 × 4), which differ from actual planed dimensions (1½ × 3½ in). Misapplication of nominal values inflates calculated BF by 14 percent:

Nominal BF (2×4×8) = (2 × 4 × 8) ÷ 12 = 5.33 BF Actual BF (1.5×3.5×8) = (1.5 × 3.5 × 8) ÷ 12 = 3.5 BF

Contract specifications must clarify which measurement basis applies to prevent discrepancies.

Rounded and Fractional Measurements

Precision in mixed-unit multiplication can be compromised by intermediate rounding. Best practice defers rounding until final results, retaining at least four significant digits during computation. For instance, a 1⅜ in thickness should be entered as 1.375 in, not 1.4 in, to limit cumulative error.

Digital Tools and Automation

Web-Based Calculators

Platforms such as OmniCalculator feature lumber volume calculator modules accessible via browser or mobile. A typical interface prompts entry of T, W and L, returning results in under a second. “This board feet calculator allows you to quickly estimate the volume of hardwood lumber you want to buy,” according to user reviews. [OmniCalculator]

Software Integration

In industrial sawmills, scanning systems employ laser or structured light to capture board dimensions. Proprietary algorithms integrate a board feet equation into cutting optimization software, reducing manual input. Reported mean absolute error rates for 3D scanning systems fall below 3 percent, enhancing throughput and minimizing waste. [Forest Analytics]

Mobile Applications

Applications such as ProTrack and WoodCalc harness smartphone sensors to measure board surfaces. While offering on-site convenience, their accuracy hinges on device calibration; internal trials reveal a standard deviation of ±0.25 in in thickness measurement, translating to ±0.5 BF error in a 2 × 8 × 10 ft board.

Common Calculation Pitfalls

- Unit Mismatch: Failure to convert between inches and feet, leading to 12-fold miscalculations.

- Nominal Dimension Confusion: Applying nominal sizes to finished boards without adjustment, skewing totals by up to 30 percent.

- Early Rounding: Rounding intermediate values inflates aggregate error in multi-board projects.

- Ignoring Defects: Overlooking wane, knots or warp can falsely increase effective board footage.

Applications Across Industries

Construction and Carpentry

Accurate estimation of how to calculate board feet informs ordering of framing, flooring and finish carpentry materials. General contractors report a 7 percent reduction in over-order costs when standardized BF protocols replace eyeballed estimates.

Forestry and Logging

Forest managers rely on log scaling formulas to project yield and revenue. Combining mill-scale data with GIS-based inventory models improves stump-to-yard revenue forecasts by an average of 12 percent, as reported in a 2023 study of Pacific Northwest timberlands. [Forest Ecology and Management]

Lumber Trading and Pricing

The commodity price of U.S. softwood lumber closed at 562 USD per 1,000 BF on December 31, 2025, equivalent to 0.562 USD per BF. [Trading Economics] Traders and buyers negotiate contracts based on BF calculations, making precision in board foot formula application directly material to cost management.

Educational and Training Aspects

Vocational schools and certification programs incorporate board foot exercises into curricula, emphasizing real-world scenarios. Instructors note that students grasp volumetric concepts more readily through hands-on workshop tasks, such as measuring mixed-dimension stock and reconciling manual calculations with digital tools. A 2022 survey of carpentry trainers found 88 percent recommend early exposure to how to calculate board feet as foundational to statistical process control in manufacturing contexts.

Final Considerations

Grasp of the board foot formula and its operational context remains central to material efficiency, cost control and quality assurance across wood-based industries. Whether performed manually through precise measurement and arithmetic or automated via digital scanning and web-based board feet calculator tools, accurate calculation guards against waste and budget overruns. A disciplined approach—clarifying nominal versus actual dimensions, deferring rounding, accounting for defects and leveraging validated software—reinforces reliability. As industry continues toward automation and data integration, the fundamental principles of board foot calculation endure as a testament to pragmatic measurement science.